summarized:Abstract:The OUYI GM Junction Box represents a pinnacle of design for harsh environment electrical connectivity. This comprehensive technical analysis explores the GM Junction Box's construction, IP68 certification, material science, diverse application scenarios across multiple industries, inst

[The IP68 Imperative: Understanding the Rating](#23-the-ip68-imperative-understanding-the- rating)

Comparative Analysis: GM Junction Box in the Market Landscape

Future Trends & the Evolution of Harsh Environment Connectivity

Electrical connections in harsh environments face significant challenges that can compromise system integrity, safety, and reliability. The OUYI GM Junction Box represents a pinnacle of design specifically engineered to address these challenges.

Consequences of Connection Failure:

Safety hazards including short circuits and electrocution risks.

Costly system downtime and operational interruptions.

Expensive maintenance and repair requirements.

Premature equipment failure and replacement costs.

Defining the Requirements:Effective harsh environment connectivity solutions must provide:

Superior waterproofing and dustproofing capabilities.

Chemical resistance to industrial and environmental agents.

Exceptional mechanical strength and impact resistance.

UV stability for long-term outdoor performance.

Temperature resilience across extreme operating conditions.

The OUYI GM Junction Box has been purpose-built to meet and exceed these demanding requirements, providing engineers with a reliable solution for critical applications.

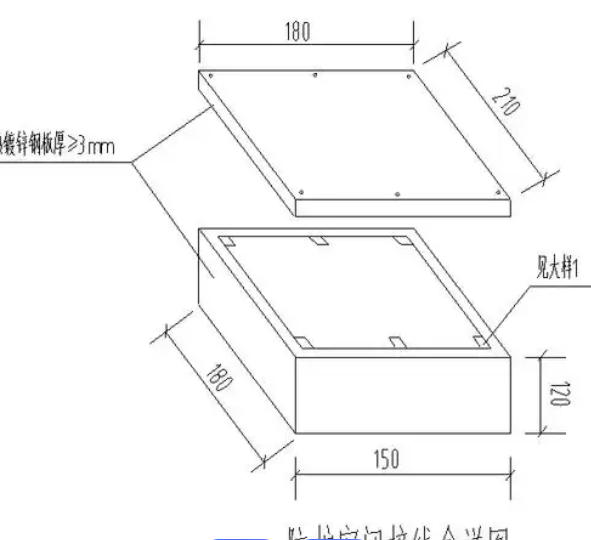

| Specification | Value | | :--- | :--- | | External Dimensions | 72mm (L) x 65mm (W) x 36mm (H) | | Wire Section Capacity | 0.5 mm² to 2.5 mm² (AWG 20 to AWG 14) | | Minimum Wire Size Outer Diameter (OD) | Two variants: 5-9mm OD and 9-12mm OD | | Supply Voltage Rating | 24A / 450V AC | | Wire Connect Type | 3P (3 Positions/Poles) | | Safety Certifications | TUV, SAA, CE, RoHS standards |

Enclosure Material: Polycarbonate (PC) - Offers high impact resistance (IK rating equivalent), exceptional clarity for visual inspection, inherent UV stability (resists yellowing and embrittlement), and good flame retardancy (UL94 V-0/V-2 likely).

Seals & Grommets: Silicone or EPDM - Provide excellent temperature range (-40°C to +120°C+), permanent elasticity, and superior water resistance.

Terminal Blocks/Connectors: PA66 (Nylon 66) - Delivers high mechanical strength, good electrical insulation, resistance to fuels, oils, and many chemicals, with excellent creep resistance under load.

The IP68 rating represents the highest level of protection against environmental factors:

First Digit (6): Complete protection against dust ingress.

Second Digit (8): Protection against continuous immersion under pressure (typically >1m depth, as specified by manufacturer).

Testing Standards & Real-World Performance:The GM Junction Box undergoes rigorous testing according to IEC 60529 standards to achieve its IP68 rating. This translates to real-world protection against:

High-pressure water jets and washdowns.

Submersion in floods or enclosures filling with water.

Dust storms and fine particulate matter infiltration.

Long-term exposure to challenging environmental conditions.

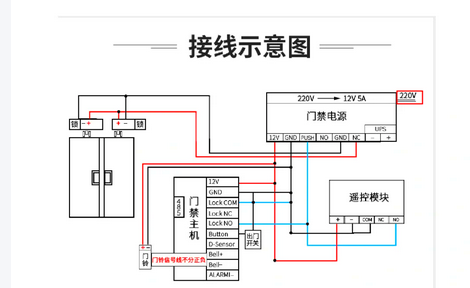

The GM Junction Box is designed to maintain electrical integrity in demanding conditions:

Rated for 24A / 450V AC applications.

Accommodates wire sizes from 0.5 mm² to 2.5 mm² (AWG 20 to AWG 14).

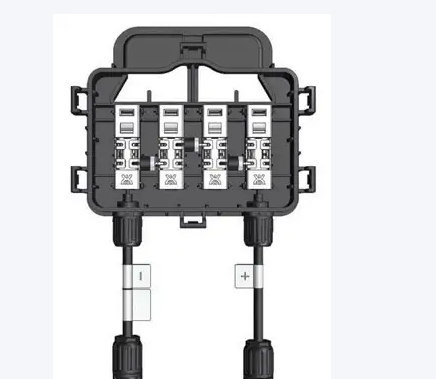

Three-position terminal blocks for secure connections.

Compatible with standard cable glands (M20, M25, PG7, PG9, etc.).

Transparent Lid: Enables visual inspection of connections without opening the box, maintaining seal integrity and preventing environmental contamination.

Robust Clamping Mechanism: Ensures constant pressure on seals for long-term waterproofing performance, even under vibration and thermal cycling conditions.

Acid & Alkali Resistance: Withstands exposure to industrial cleaning agents, agricultural chemicals, and saline atmospheres without degradation.

"Non-Tearing" Construction: Refers to the resilience of the PC material against cracking or splitting under impact or stress, ensuring long-term durability.

Lighting & Illumination: Outdoor LED lighting (streetlights, bollards), architectural facade lighting, tunnel lighting, garden/landscape lighting, LED billboards, sports field lighting.

Renewable Energy Systems: Solar PV combiner box connections, small wind turbine bases, solar water heater roof connections, outdoor inverter connections.

Industrial Automation & Machinery: Outdoor machinery (food processing washdowns), agricultural equipment, control panel external I/O, conveyor systems, sensor/actuator connections.

Marine & Coastal Environments: Marina/dock lighting, boat deck wiring, coastal infrastructure (boardwalks), monitoring equipment, desalination plants.

Infrastructure & Utilities: Underground utility pull-boxes, traffic signal controllers, EV charging stations, water/wastewater treatment plants, telecom outside plant (OSP) equipment.

Mining & Resource Extraction: Surface/underground mining equipment, exploration sensor junctions, processing plants.

Telecommunications: CCTV/security camera connections, remote cabinet wiring, buried enclosure connections.

Proper installation is critical to achieving the promised IP68 performance.

Preparation:

Ensure the box, cables, and cable glands are clean and undamaged.

Select the correct cable gland variant (5-9mm or 9-12mm) for your cable's outer diameter.

Strip cable insulation to the appropriate length as per terminal block requirements.

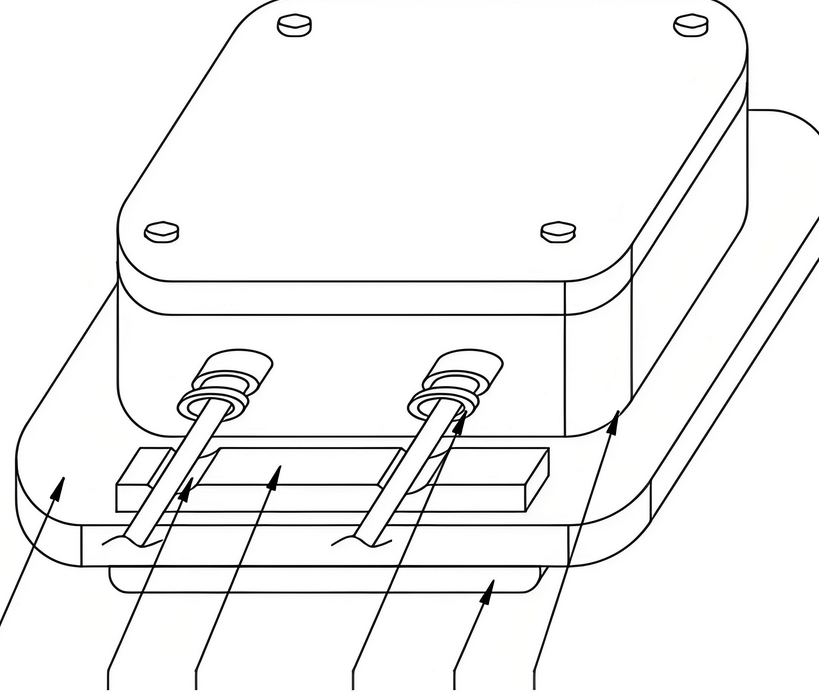

Cable Gland Installation:

Thread the cable through the gland's nut, seal, and body before stripping.

Insert the cable into the junction box entry port.

Hand-tighten the gland nut onto the box, then use a tool to secure it firmly. Avoid over-tightening, which can damage the threads or crack the housing.

Wiring:

Connect the wires securely to the terminal blocks, ensuring no loose strands.

Tighten terminal screws to the specified torque (if available) to ensure a reliable electrical connection without damaging the conductor.

Sealing:

Carefully route the cables inside the box to avoid pinching.

Ensure the silicone seal is properly seated in its groove and free of debris.

Close the lid and evenly tighten the clamping screws in a cross pattern. This ensures uniform pressure on the seal for a perfect, watertight closure.

| Feature | OUYI GM Junction Box | Standard Plastic Enclosure | Basic DIY Solutions (e.g., Tape) | | :--- | :--- | :--- | :--- | | Ingress Protection | IP68 (Dust-tight, Submersible) | IP54 / IP65 (Dust & Splash resistant) | None (Vulnerable) | | Durability | High-Impact PC, UV Stable | Standard ABS, may degrade in sun | Very Low | | Long-Term Reliability | Excellent (Engineered seals & materials) | Moderate (Seals can degrade) | Poor (Guaranteed to fail) | | Safety Certification | TUV, SAA, CE, RoHS | May lack full certification | None | | Maintenance | Visual inspection without opening | Must open to inspect, breaking seal | Requires full rework | | Total Cost of Ownership | Low (Prevents downtime & repairs) | Medium | Very High (Due to failures) |

The GM Junction Box is positioned as a premium, engineered solution. While its initial cost is higher than non-rated alternatives, its value is realized through eliminating failure costs, ensuring safety, and minimizing downtime over the entire lifecycle of the installation.

The GM Junction Box directly tackles key industry challenges:

Increasingly Harsh Environments: Climate change leads to more extreme weather; industrial processes become more demanding. The GM's robust construction is built for these conditions.

Demand for Reliability & Uptime: System failures are more costly than ever. The GM provides a proven, certified layer of protection to maximize operational availability.

Safety Regulations: Compliance with international safety standards (TUV, CE) is non-negotiable. The GM simplifies compliance for end products.

Lifecycle Cost Reduction: By specifying a component that won't fail prematurely, engineers reduce the total cost of ownership through avoided maintenance and replacements.

Integration with IIoT: Future iterations may include built-in sensors for moisture detection, temperature monitoring, or connection integrity reporting, feeding data into Industrial IoT platforms for predictive maintenance.

Advanced Materials: Development of even more resistant polymers and composites for broader chemical compatibility and higher temperature ranges.

Modular & Scalable Designs: Junction systems that allow for easy daisy-chaining or expansion to accommodate more connections without compromising the seal.

Simplified Installation Tools: Push-in or spring-cage terminal technology could be integrated to speed up wiring and reduce installation errors.

The OUYI GM platform is well-positioned to evolve with these trends, maintaining its role as a foundational component for protected electrical systems.

When specifying or procuring the GM Junction Box, ensure you:

Confirm Environmental Needs: Verify the need for IP68 vs. a lower rating. Is submersion a real risk?

Select the Correct Variant: Choose the model based on cable outer diameter (5-9mm or 9-12mm).

Check Certifications: Ensure the product has the necessary certifications (TUV, CE) for your target market and application.

Plan for Installation: Source the correct M20/PG-sized cable glands and tools for a proper installation.

Supplier Qualification: Purchase from authorized distributors like OUYI to guarantee product authenticity and performance.

Specification Line Item Example:

Junction Box, Polycarbonate, IP68, 72x65x36mm, 3-Pole Terminal Block (0.5-2.5mm²), 24A/450VAC, TUV/CE Certified, for 5-9mm OD Cable.

The OUYI GM Junction Box is far more than a simple container for wires. It is a critically engineered component designed to ensure the integrity, safety, and longevity of electrical systems operating in the world's most challenging environments. By providing guaranteed IP68 protection, robust construction, and user-friendly features like a transparent lid, it offers engineers and installers a reliable, cost-effective solution that mitigates risk and prevents costly failures. In an era where connectivity is vital and downtime is unacceptable, the GM Junction Box stands as an indispensable element of robust system design.

IEC 60529: Degrees of protection provided by enclosures (IP Code)

OUYI Product Datasheet: GM Series Waterproof Junction Box

UL 94: Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances

IEC 60670-1: Boxes and enclosures for electrical accessories for household and similar fixed electrical installations

----guide)